|

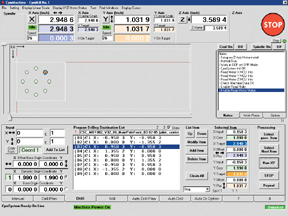

Characteristics of the CompuMill System:

- No G-code or M-code required for programming

- True GUI (User Graphic Interface)

- Multiple programming methods built-in

- Soft and Hard Emergency Stop Buttons

- Sensor detects the rotation speed of the spindle motor and is able to respond appropriately to abrupt changes in rotational speeds (optional)

- Optional accessories include touch sensor and indicator interfaces

- Optional accessory includes programmable rotary table

Inside of CompuMill

Features of CompuMill Navigator

- Programmable computer-controlled coolant dispensing system

- Three different ways of tracking the target position

- Changing motor speed on the fly during job processing

- Synchronous toolpath display

- Variable view window with zoom in and out capabilities

- Multiple programming methods built-in, such as Off-Line programming, Single Move, Drilling and Milling

- Multiple tool offsets in the same process

- User definable milling method library

Accessories - Programmable Rotary Table

Programmable rotary table can cut gears with any number of teeth without any indexing plates. The resolution of positioning is 0.01 of a degree. The programmable rotary table can be directly linked with our system for continuous helical milling. It is also a stand-alone unit that can be programmed without linking to a computer system.

Features of The Rotary Table:

- The work table is graduated 360 degrees around its circumference and is driven by a precise Worm and Gear, providing a 90:1 reduction ratio.

- One turn of the handle moves the table through 4 degrees.

- Both the upper and the lower surface are precision ground.

- The dial is graduated in divisions of 1 minimum and the vernier scale allows readings down to 10 seconds.

- The Worm is hardened and precision ground to minimize wear of the worm gear.